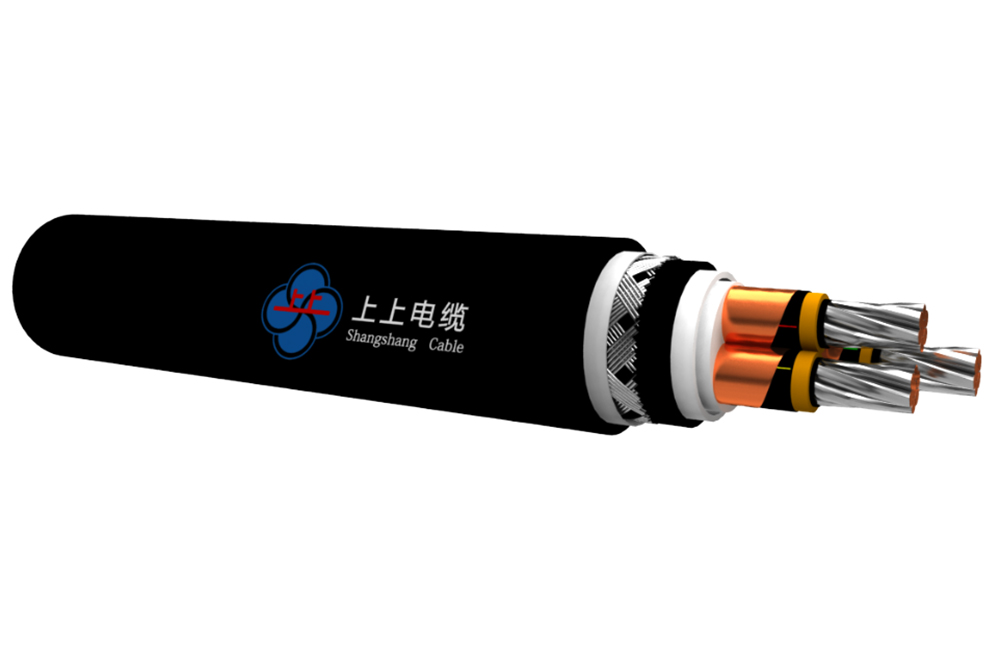

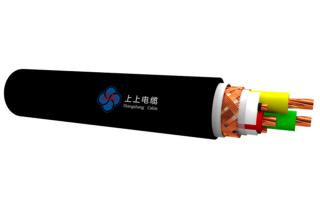

The VFD cables are used in power transmission system from variable frequency drives to AC motor with rated voltage upto and including 26/35kV. It has good shielding properties, anti-electrostatic coupling, anti-electromagnetic induction, anti-electromagnetic wave, anti-poor grounding and anti-electromagnetic interference, etc. The cable is intended for fixed installation and laying outdoor and indoor, direct burial, cable conduit and trench.

STANDARDS:

GB/T12706, IEC60502-2, Q/320481SS168, IEC60228

- Conductor: stranded compacted circular plain copper wires, class 2 as per IEC60228

- Insulation: XLPE

- Individual Screen: copper tape(CTS), or copper wires + copper tape(CWS+CTS)

- Filler: Polypropylene yarn

- Assembly binder tape

- Overall Screen: copper tape(CTS), or copper wires + copper tape(CWS+CTS), or copper wire braided (CWB)

- Inner covering/inner sheath(optional): PVC or PE

- Armour(optional): galvanized steel tape(DSTA), or galvanized round steel wire(SWA)

- Outer sheath: PVC

3-core:Copper 25mm2 ~ 300mm2

CORE IDENTIFICATION:

Core identification: by coloured plastic tape of brown, black, grey

Note: Other method can be available upon request.

SHEATH COLOR:

Black, or other color upon request.

USAGE CHARACTERISTIC:

Voltage:3.6/6(7.2)kV, 6/10(12)kV, 8.7/15(17.5)kV, 12/20(24)kV, 18/30(36)kV, 26/35(40.5)kV

Maximum continuous operating temperature of conductor:90℃

Maximum short-circuit temperature (Max. duration 5Sec.): 250℃

Minimum ambient temperature for installation:0℃

Minimum bending radius when installation: 15 D ( D is the overall diameter of cable)

Special Features on Request:

Flame retardant (Acc. to IEC60332-3)

Low smoke zero halogen

Anti-termite/anti- rodent

Use in low ambient temperature

UV resistant