Thermocouple cable shall be one pair or multi-pair and insulated with the same Pyro-EMF value of matched thermocouple within certain temperature. They are used to connect thermocouple and measuring devices to compensate the error resulting from temperature change on connection part. This cable includes two types of thermocouple extension cable and thermocouple compensational cable.

This cable is suitable for signal transmission, instrument measurement. Used for indoor or fixed installation, in cable tray or conduit to connect different types of thermocouple in industrial process controls, refineries, oil and gas plants, etc.

STANDARD:

GB/T 4989, GB/T 7495, GB/T 4990, IEC 60584, BS 5308, BS EN 50288-7, ANSI 96.1,

or other standards upon request.

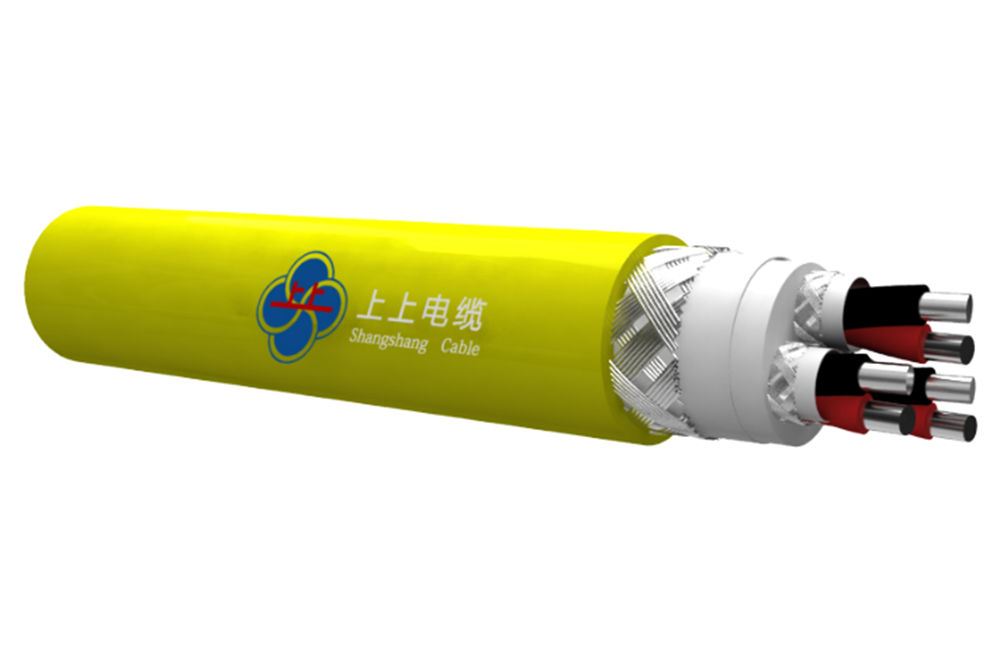

CONSTRUCTION:

1. Conductor:alloy wire of positive and negative,see table 1 below for details

2. Insulation:(1) for general purpose: PVC, or PE, or XLPE;

(2) for heat resistant cable:fluorine plastic or silicone rubber

3. Binder tape

4. Individual screen(optional):copper tape, or copper wire braid, or aluminum(or copper) - plastic laminated tape with tinned copper drain wire

5. Filler

6. Binder tape

7. Overall screen (optional):copper tape, or copper wire braid, or aluminum(or copper) - plastic laminated tape with tinned copper drain wire

8. Inner sheath(optional): for general purpose: PVC, or PE, or LSZH flame retardant polyolefin

9. Armour(optional) : galvanized steel tape, galvanized steel wires armour, fine galvanized steel wire braid

10. Outer sheath: (1) for general purpose: PVC, or PE, or LSZH flame retardant polyolefin;

(2) for heat resistant cable:fluorine plastic, or silicone rubber

Note:

1. Extruded inner sheath and armour layer are not applicable to non-armoured cable;

2. Aluminum (or copper) plastic laminated tape screen, extruded inner sheath and armour layer are not applicable to heat resistant fluorine plastic cable

table 1——Conductor type

|

Type of Thermo- couple |

Code of compensation conductor |

Conductor—Positive |

Conductor—Negative |

||

|

|

|

name |

code |

name |

code |

|

S |

SC |

CU |

SPC |

CuNi0.6 |

SNC |

|

R |

RC |

CU |

RPC |

CuNi0.6 |

RNC |

|

K |

KCA |

Fe |

KPCA |

CuNi22 |

KNCA |

|

K |

KX |

NiCr10 |

KPX |

NiSi3 |

KNX |

|

N |

NC |

Fe |

NPC |

CuNi18 |

NNC |

|

N |

NX |

NiCr14Si |

NPX |

NiSi4Mg |

NNX |

|

E |

EX |

NiCr10 |

EPX |

CuNi45 |

ENX |

|

J |

JX |

Fe |

JPX |

CuNi45 |

JNX |

|

T |

TX |

CuFe |

TPX |

CuNi45 |

TNX |

Temerature garde, Number of pairs and sizes:

| Temperature grade |

Error allowance grade & mark code |

Number of pairs |

Conductor Sizes

(mm2)

|

||

|

Category |

Mark code |

Common grade |

Precision grade |

||

|

General purpose |

G |

Omitted |

S |

1~12 pair |

0.5、1.0、1.5、2.5 |

|

Heat resistant |

H |

1~7 pair |

0.5、1.0、1.5、2.5 |

||

CORE IDENTIFICATION AND SHEATH COLOUR

| Type of Compensation conductor |

Insulation core colour |

Sheath Colour |

||||

|

Positive |

Negative |

Common grade

(code: omitted)

|

Precision Grade |

|||

|

general purpose (Code: G) |

Heat resistant grade (Code: S) |

|||||

|

SC or RC |

red |

green |

black |

grey |

yellow |

|

|

KCA |

red |

blue |

black |

grey |

yellow |

|

|

KX |

red |

black |

black |

grey |

yellow |

|

|

NC |

red |

grey |

black |

grey |

yellow |

|

|

NX |

red |

grey |

black |

grey |

yellow |

|

|

EX |

red |

brown |

black |

grey |

yellow |

|

|

JX |

red |

purple |

black |

grey |

yellow |

|

|

TX |

red |

white |

black |

grey |

yellow |

|

Note: other core color and sheath color is available upon request as per other standard

USAGE CHARACTERISTIC:

Maximum operating temperature and short circuit temperature:

| Insulation materials | J-70PVC,PE | J-90PVC, J-105PVC XLPE | Silicone rubber | F46 | PFA |

| Maximum continuous operating temperature (℃) | 70 | 90, 105 | 180 | 200 | 260 |

| Short circuit temperature (Max. duration 5s) (℃) | 160 | 250 | 350 | 350 | 350 |

Minimum bending radius when installation:

-For heat resistant cable: 12xO.D.

-For general purpose: 12xO.D.(screened and armoured), 6xO.D.(un-screened and unarmoured)

Special Features on Request:

Flame retardant

Fire-resistant

Low smoke zero halogen

Anti-termite/anti-rodent

Used in low ambient temperature

UV resistant

Mineral oil resistant

Intrinsically safe (sheath colour blue)