These cables are suitable for the interconnection of electronic computers, testing instruments and control system instruments with high anti-interference performance requirements, and for high anti-interference analog data transmission at high temperature occasions. To resist electromagnetic interference, these instrumentation cables shall have whether an overall screen or individually screen and collectively screen.

STANDARD:Enterprise standard Q/320481SS111, Or other standards upon request

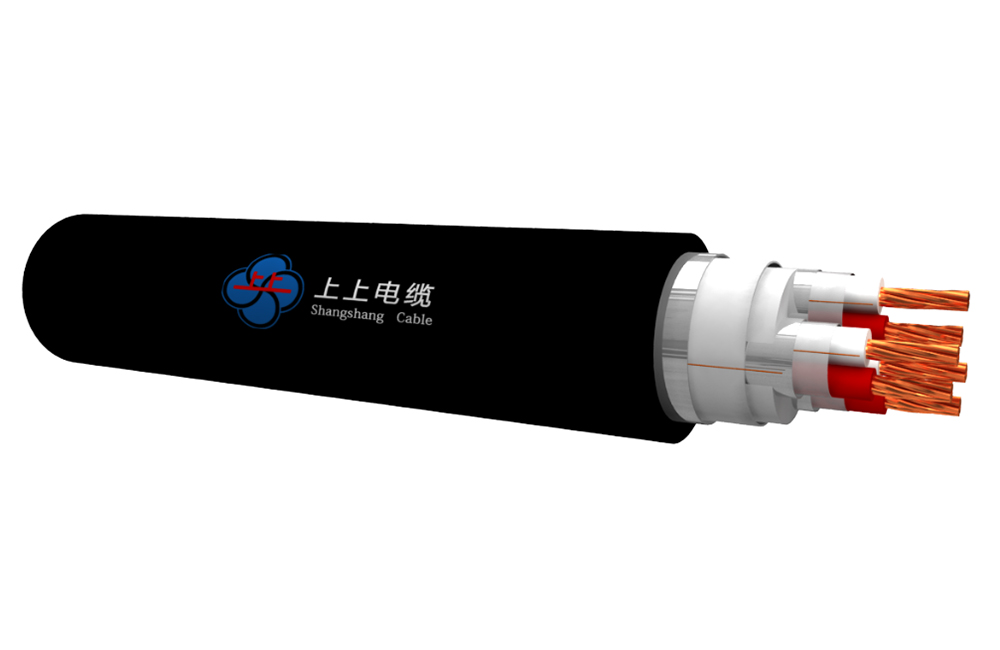

CONSTRUCTION:

1.Conductor: plain or tinned copper wires, Class 1/Class 2/Class 5 as per IEC60228

2.Insulation:silicone rubber

3.Elements: twisted in pairs, triads.

4.Metallic screen: individual screen and/or overall screen with copper wire braided (BCWB or TCWB), or copper tape(CTS)

5.Outersheath: silicone rubber

NUMBER OF CORES AND CONDUCTOR SIZE:

|

Elements |

Number of element |

Conductor CSA(mm2) |

|

Pairs |

1 pair ∽ 19 pairs |

0.5, 0.75, 1.0, 1.5, 2.5 |

|

Triads |

1 Triad ∽ 19 triad |

0.5, 0.75, 1.0, 1.5, 2.5 |

INSULATION CORE IDENTIFICATION:

Single pair: red, blueMulti-pair: red, blue with printed numbers of pairs

Single triad: yellow, green, red

Multi-triad: yellow, green, red with printed numbers of pairs

Note: other core identification method is available upon request

OUTER SHEATH COLOR

Black; or other color upon request

USAGE CHARACTERISTIC:

Voltage range: 300/500V

The continuous operating temperature: 180℃

The maximum cable temperature with short circuit (5S): 350℃

The minimum ambient temperature for installation: 0℃

The minimum bending radius during installation: 15D

SPECIAL FEATURES ON REQUEST:

Flame retardant

Fire resistant (mica tape shall be applied over the conductor)

Low temperature use

UV resistant

LSZH or PVC sheath